How to reduce the Carbon Footprint

Several studies have shown that plastics have a lower carbon footprint than other materials such as glass, aluminium or paper. The use of recycled plastics, in particular, can have a positive impact on carbon emissions: recycling sistems that produce recycled plastics generate fewer emissions than traditional raw material extraction processes.

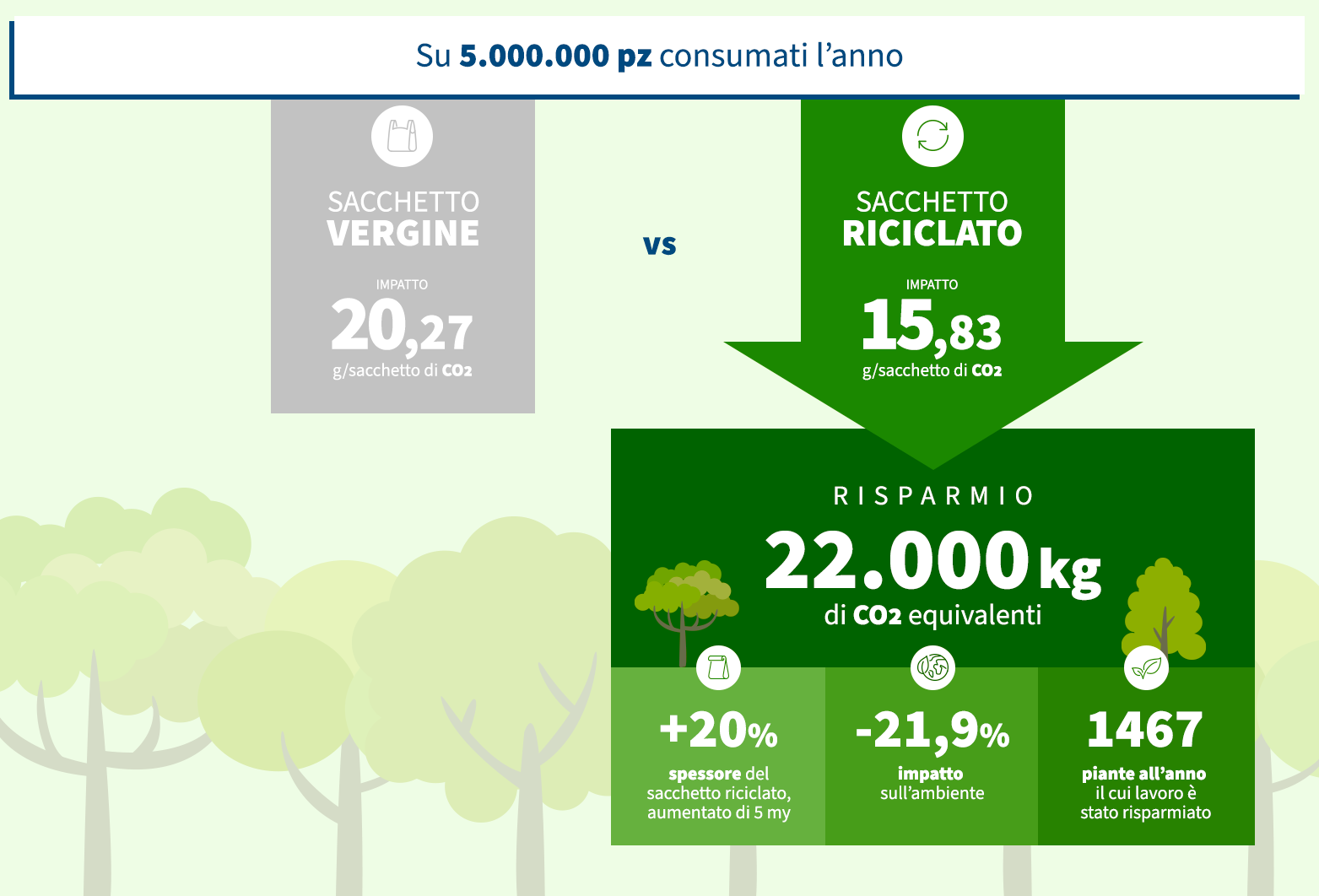

Incorporating more recycled plastic into products and packaging (such as the use of regenerated PE in the case of plastic bags) can therefore be ab effective way to reduce the carbon footprint.

Although recycled plastic has a lower carbon footprint than traditional alternatives, in a fully-functioning circular economy the way in which the material is disposed of and recycled is crucial to allow emissions to be reduced: in order to increase the recycled content within bags and packaging, a suffiecient supply of recycled plastic material must be available. It is therefore important that consumers also contribute to proper plastic recycling through conscious separate collection, separating products correctly and trying to limit waste.

In order to reduce the Carbon Footprint, in the case of plastic bags used for waste collection, it is also useful to pay attention ti the optimal filling level of the level of bags, so as to decrease the number of bags used and thus also the number collections by the companies providing the service.

+39 0376 391192

+39 0376 391192