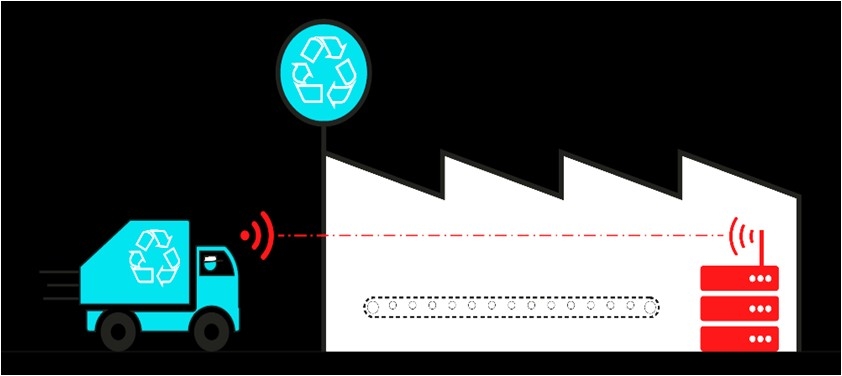

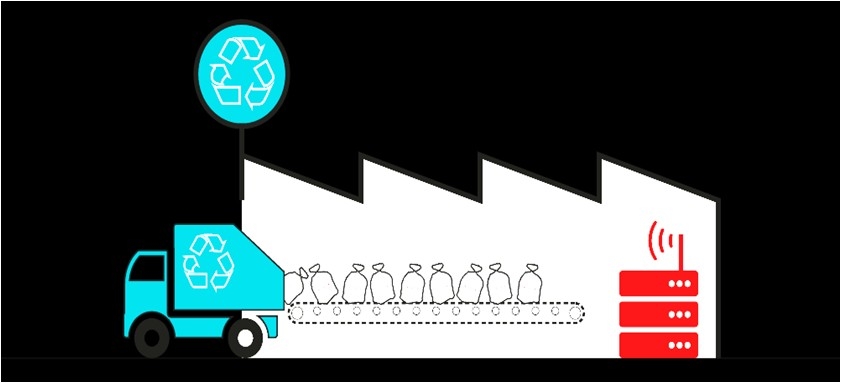

The PE waste collection bags can be made for any type of bin or container, both large and small. Indeed, all bags are made of PE with different sizes, formats and thicknesses, according to the target content. Bag colors too can be customized (since bags are made of neutral colors), depending upon contents, which can be paper, plastic, glass, aluminum or even other special kinds of industrial waste. We take care of the production of QRcode on polyethylene products, so as to ensure maximum level of reliability.

Technical specifications of PE waste collection bags

Our PE waste bags can be made with these specifications:

- MATERIAL: HDPE/LDPE/BIODEGRADABLE/COMPOSTABLE

- THICKNESS: from 10 to 250 micron

- WIDTH: up to 135 cm

- CLOSING: open-mouthed

- LIQUID SEAL: yes

- BIODEGRADABLE: on request

- TYPE: reel, rolls, bulk or bundles

- TRACEABILITY: yes (Barcode, QR code, Tag-Rfid)

+39 0376 391192

+39 0376 391192